Sometimes big leaps forward come from accidental missteps. Find out how waste onions were transformed into a technical puffer jacket at the very pinnacle of eco innovation.

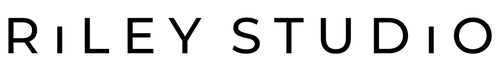

When the canteen staff at the Komatsu fabric mill in Japan noticed that their pristine white rubber boots were being stained by onion skins that fell onto the kitchen floor, they were probably not pleased. But when members of the mill’s fabric innovation team spotted the same thing, it sparked their imagination.

Natural dyeing with plants and food waste is an ancient practice that dates back some 4,000+ years. However, this natural method has always been limited to small batches and organic fabrics, like cotton and linen, producing unique but unpredictable results.

In contrast, industrial fabric dyeing is often the most harmful stage in the production process for any garment. Dyeing uses vast amounts of water, and synthetic dyes contain toxic chemicals that can leach into the surrounding water system, causing untold environmental damage.

That’s why the onion incident in the Komatsu kitchen got the Japanese mill’s fabric technicians so excited. What, they thought, if they could harness the natural power of food waste dyes and apply them to manmade fibers on a large scale?

After years of extensive research and development, Komatsu launched Onibegie - the world’s first pigment dye series that works on man made fabrics, as part of a low impact and environmentally friendly dyeing process.

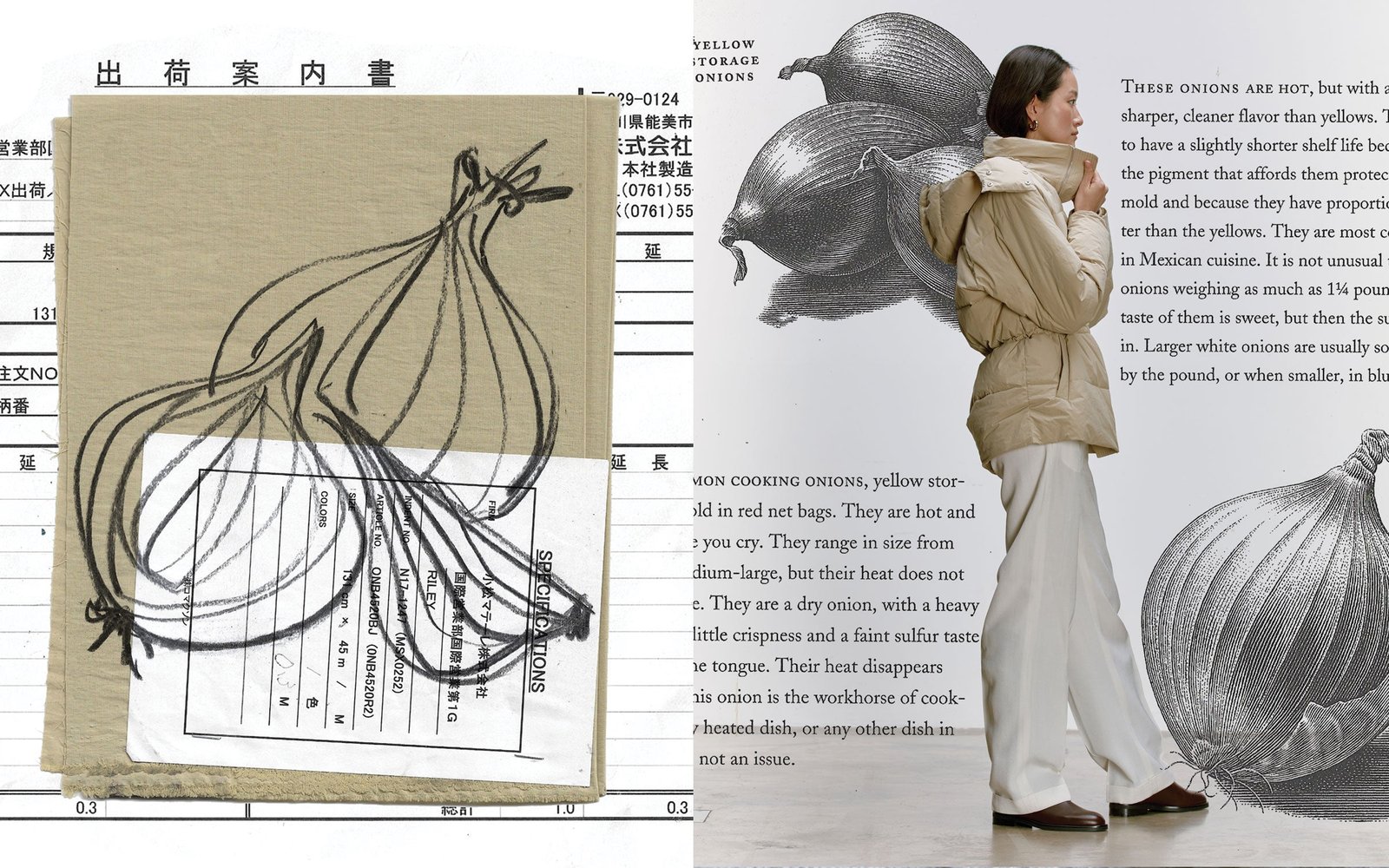

As soon as we heard about this innovative new dying series we knew we had to make something. Creating a gender free puffer jacket had been high on our list for a long time and this low impact dying process opened up a new palette of recycled technical fabrics for us to play with.

For the final jacket, we settled on a technical recycled nylon with a slight crinkled finish. This recycled nylon was then dyed with waste onions skins and rice husks, which have given the fabric a soft, organic colour that is unlike anything else.

To add functionality to the jacket, the fabric wizards at Komatsu have treated the material with a flurocarbon-free water repellent, giving it showerproof qualities, while a unique compacting process means that the fabric will keep its shape for longer, prolonging the life and therefore increasing the sustainability of this technically advanced jacket.

After the fabric has been milled and dyed by Komatsu it is then passed on to Pafil in Portugal - one of our trusted manufacturers. At Pafil the recycled nylon outer is filled with innovative insulation created from plastic bottles diverted from landfill. This low impact alternative to down is created by our friends at Freudenberg in Germany.

At the end of this long and complex journey, our Recycled Nylon Food Waste Puffer Jacket represents a huge jump forward in eco innovation. We’re so excited to be able to share it with you.

Back to Our Journal